Baking the chambers and instruments

Once the ultra high vacuum components are exposed to the atmosphere, they require baking at high temperature (usually 110°-150 °C) in order to release various contaminants from the walls of the chambers.

Our ARPES chambers are usually baked at 120 °C for 72 hours after various maintenance and upgrade works. In order to bake the chambers follow the steps:

- Switch off the manipulator motor driver electrics. Disconnect the motor cables. Remove the motors. Leave the screws on the manipulator.

- Remove all the junction boxes and cables.

- Remove camera and cables.

- Remove the slit wheel knob. Note down the reading or make sure nobody changes the knob wheel while detached.

- Remove high voltage isolators for the Mott detector.

- Remove all other components that cannot be baked e.g., LED lights, cameras, cooling water pipes.

- Cover all the windows, and feed through by aluminum foil.

- Setup the baking tents.

Note: Due to improper interlock configuration, currently the baking controller requires the cryopump to be ON while baking.

After the baking is complete, allow sufficient time (about one whole day) for the chamber to cool down. Do not remove the baking tent or aluminum foils until the chamber reached near room temperature. Sudden temperature change might cause cracks in the viewports and feed-throughs.

Reference log

For you reference of various conditions, here is sample logbook:

11/Mar/2019

We are preparing the bake out of analyzer and preparation chamber.

Chamber pressure before we started:

Analyzer : 4.34 ✕ 10-8 mbar

Spin : 1.13 ✕ 10-8 mbar

Prep : 2.72 ✕ 10-8 mbar

Buffer : 3.94 ✕ 10-7 mbar

- Removed analyzer preamplifier junction boxes

- Removed slit wheel knob (analyzer slit = 500)

- Removed detector camera

- Remove x-ray source water supply and connections.

Baking the chamber for 68 hours at 120 °C.

Baking started at 14:36 hrs.

At 16:00, temperature reached 78 °C. Started TSP. 5 days 10 hours, sublimate every 3 hours.

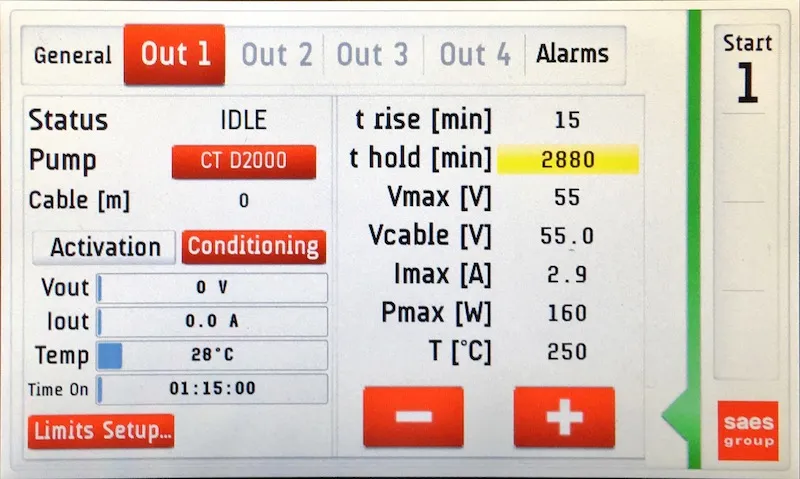

Started NEG pump in conditioning mode.

Settings for NEG conditioning:

Maximum time can be set for conditioning is 48 hours. We need to restart the NEG conditioning after 48 hours or before. During conditioning, the NEG temperature reaches 250 °C.

Chamber pressure at 17:30

Analyzer : 3.88 ✕ 10-7 mbar

Spin : 2.36 ✕ 10-7 mbar

Prep : 5.80 ✕ 10-7 mbar

Buffer : 3.60 ✕ 10-6 mbar

Readings on the gauges, NOT on the PCUs.

12/Mar/2019

Chamber pressure at 11:00

Analyzer : 2.99 ✕ 10-7 mbar

Spin : 9.96 ✕ 10-8 mbar

Prep : 3.55 ✕ 10-7 mbar

Buffer : 2.18 ✕ 10-6 mbar

Chamber pressure at 17:30

Analyzer : 2.16 ✕ 10-7 mbar

Spin : 7.70 ✕ 10-8 mbar

Prep : 2.30 ✕ 10-7 mbar

Buffer : 1.68 ✕ 10-6 mbar

13/Mar/2019

Chamber pressure at 11:30

Analyzer : 1.13 ✕ 10-7 mbar

Spin : 4.71 ✕ 10-8 mbar

Prep : 1.23 ✕ 10-7 mbar

Buffer : 1.03 ✕ 10-6 mbar

Chamber pressure at 17:15

Analyzer : 9.58 ✕ 10-8 mbar

Spin : 4.19 ✕ 10-8 mbar

Prep : 1.04 ✕ 10-7 mbar

Buffer : 8.90 ✕ 10-7 mbar

14/Mar/2019

Chamber pressure at 11:25

Analyzer : 6.96 ✕ 10-8 mbar

Spin : 3.43 ✕ 10-8 mbar

Prep : 7.08 ✕ 10-8 mbar

Buffer : 7.18 ✕ 10-7 mbar

11:30 HRS

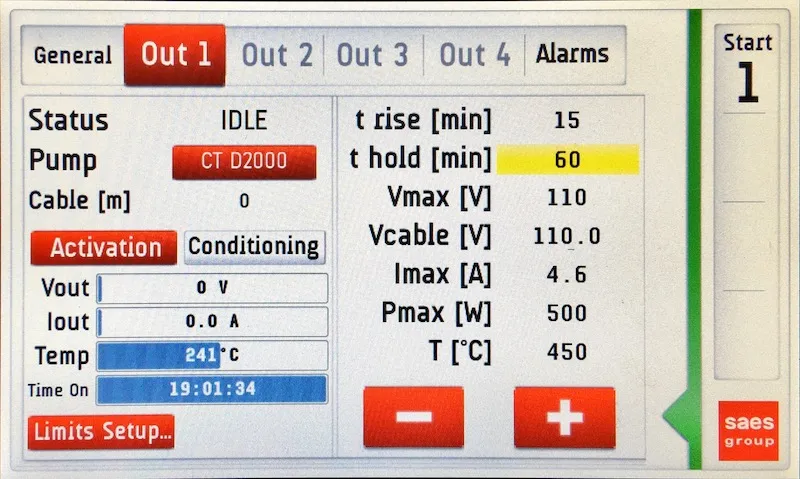

Starting NEG Activation

trise = 15 min

thold = 60 min

T = 450 °C

Pressure is increasing after NEG activation. After 19 minutes, status is HOLD, temperature is 335 °C.

Analyzer : 9.90 ✕ 10-6 mbar

Spin : 3.31 ✕ 10-6 mbar

Prep : 2.84 ✕ 10-6 mbar

Buffer : 3.87 ✕ 10-5 mbar

After this point, pressure started recovering, though the temperature kept rising.

After one hour (15 minutes trise and 45 minutes thold), NEG activation temperature reached 433 °C.

Maximum temperature reached by NEG pump = 441 °C

Vout = 95 V

Iout = 3.9 A.

The baking heaters and the NEG activation going to stop almost at the same time.

Baking stopped at 13:00

Chamber pressure:

Analyzer : 1.12 ✕ 10-7 mbar

Spin : 4.64 ✕ 10-8 mbar

Prep : 9.32 ✕ 10-8 mbar

Buffer : 8.57 ✕ 10-7 mbar

Degas the vacuum gauges at 13:55 hrs. when the temperature is 75 °C.

Gauge degas time = 15 minutes.

Chamber pressure at 17:40

Chamber temperature reached 40 °C.

Analyzer : 2.35 ✕ 10-9 mbar

Spin : 1.36 ✕ 10-9 mbar

Prep : 3.80 ✕ 10-9 mbar

Buffer : 3.05 ✕ 10-7 mbar.

15/Mar/2019

Chamber pressure at 11:40

Analyzer : 2.26 ✕ 10-10 mbar

Spin : 1.72 ✕ 10-10 mbar

Prep : 4.07 ✕ 10-10 mbar

Buffer : 2.28 ✕ 10-7 mbar.